| LaymarCrafts

Woodturning |

Information |

| Dust, everyone's Problem.

We all have to put up with perhaps the

most damaging bi-product of making things on the Woodturning Lathe,

Dust, but we can do things to make life in the Workshop a little bit

Healthier and therefore benefit our well being. |

|

In the Hints & Tips Section of

this Web Site I describe a Dust Collection System I have made and here I try and

analyse its effectiveness and also highlight what I think are the key areas and

situations that determine what is the best way to trap and collect the Dust

generated during Turning and Sanding.

Firstly the anatomy of Woodturning

is different to an other major Dust Generator in the Workshop in as much as the

Workpiece, i.e. the Wood is in motion whereas with all other Woodworking

Machines the the Wood is, in principle, Static and it is the Machine Cutter that

rotates.

Also we have a situation where the

Workpiece on a Lathe is open on all sides, there is no natural catchment

chamber to which you can connect a Vacuum Extractor System as there is with most

other Machines.

So what is our Objective? Primarily

it has to be to protect ourselves from the Inhalation of Dust, if this is the

case then surely a suitable Respirator is all we need, it must therefore also be

for other reasons? in my case it is to have a near Dust Free Working Environment

as possible.

I will also admit that I will

often work at the Lathe without my Respirator in place, I know this is not good practice,

but!!!, so therefore the best Dust Control I can achieve is desirable.

If we look at the things that are relevant

and therefore perhaps understand why the Dust goes everywhere we do not want it

to go we can perhaps better understand what our problem is.

Dust will dissipate through out

any Workshop as a result of:

Airborne Dust carried in Air

Currents whether Mechanically Generated i.e. with a Fan, or Thermally Generated due

to the Draft that will be created by virtue of the fact that Hot Air rises and

Cold Air falls i.e. Thermal Currents.

Dust from the Wood being Turned

will be spread due to entrapment within the Shavings, Projection from the Tool,

typically along the Flute of a Gouge and by Centrifugal Force directly off of

the Spinning Wood.

Dust as a result of Sanding will

follow a typical pattern which is

primarily created by Centrifugal Force and as a result of the Coanda Effect.

And finally as we move around the

Workshop or whenever we Dust ourselves down we disturb and spread some Dust.

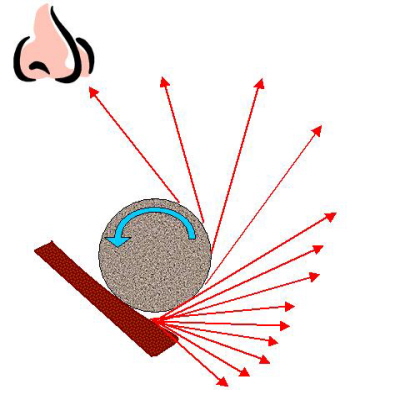

In the illustration [Fig.1] below I show a

typical situation that can be readily observed when Sanding, [ this is best done

whilst someone else does the sanding and you do the observing], which is perhaps

the biggest single process for the production of Dust, in this illustration there is no Dust

Extractor or Fan System in use this is just Sanding in natural conditions.

Fig.1

Fig.1

The actual projection and

dissipation of the Dust will be dependent on many factors:-

-

Speed of the Lathe.

-

Diameter of the Piece.

-

Combined these two points

above will give a "Tip Speed" at the point of contact.

-

The Angle at which you apply

the Abrasive, I tend to use the Abrasive at 8 O'clock.

-

The Grit Size of the Abrasive

which will determine the Dust Particle Size.

-

The Pressure at which the

Abrasive is applied.

-

The Density of the Wood due to

its type, e.g. Oak has a higher density than Pine.

-

The Density of the Dust

Particle due to the Wood Type and Grit Size of Abrasive.

-

Other factors that will play a

part are, Humidity, Position of Lathe relative to other surfaces etc.

As you can see there are 8 or 9

significant factors that you may have to consider if you are going to successfully

Trap and Collect the Dust, which will disperse differently as anyone of the

above changes.

In my case I can create a situation

where the Dust will eject itself, into the surrounding space, with a wrap around

of up to 2/3rds of

the circumference of a Piece, this however can be controlled, to a degree, by

Sanding with not too much pressure and at low speed, but such a combination is not always

convenient or practical.

So what can we do? I like many purchased a

Shavings/Dust Collector , the selection of which was based on it's Price rather than any

knowledge of what it was really capable of, and the Sales Guy at the Store assured me

it was OK for a Lathe? I now know otherwise.

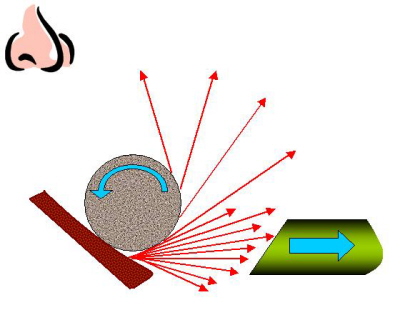

Here [Fig.2] I illustrate my

observations with only the Dust Extractor System On, using my original Unit, as detailed in

the Hints & Tips Section, which offers a more controlled Collector Nozzle

than just the Flexible Hose that I was provided with the Unit.

Fig.2

Fig.2

You will see that the Dust

Extractor has an influence on the Projection of the Dust with perhaps a maximum

wrap of no more than half way around the Piece which is an improvement but it

can be improved on.

Making the Nozzle larger is not necessarily

the solution as you are relying on the Air Intake Velocity to draw the Dust in

and by increasing the cross sectional area of the Nozzle you will reduce the

Velocity and therefore pick up less Dust, although you may well catch slightly

more of the Dust by virtue of the position of the larger Nozzle? it is a

compromise situation.

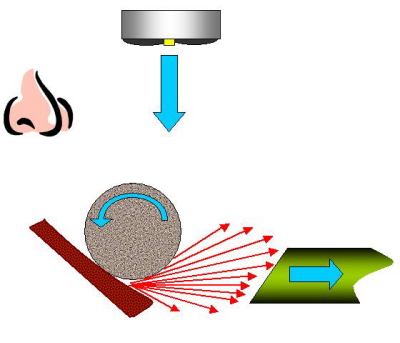

In Fig.3 I show the results I have

obtained from using the Low Level Dust Extractor Box and the Down Draft Fans

above the Lathe, again see the Hints & Tips Section, this is giving me a far better

Dust Catchment and although it could probably be improved by adding a more

Powerful Dust Extractor and Downdraft Fans there would have to be a compromise

with respect to Comfort and Noise.

Fig.3

Fig.3

The principle here is that as used in

Air Curtains, typically as utilised in Clean Rooms, where the Air Curtain contains or limits the

passage of a substance, in our case Dust, and forces it to change direction

[downwards] to

be picked up by the Dust Extractor.

If you can imagine the Fan in

Fig.3 having a reversed Air Flow, as you may have with one of the Dust Filter

Units, then it is obvious that a large portion of the Dust will be directed

upward and away from the Extractor Nozzle and therefore in direct conflict with

what you are actually attempting to do.

I feel I have a good balance with

my system and

would like to be able to quantify just how efficient it is, I was thinking of

carrying out a series of tests based on the three scenarios above by measuring, probably by Weight, the amount of Dust deposited in and around the Workshop and

the amount actually in the Dust Collection Bag of the Extractor.

This would be a worthwhile

exercise, but I am not sure I have the time and the discipline to do such a study, perhaps a Student looking for a Final Year Project might take

up the challenge.

|

LaymarCrafts Woodturning is the Web

Site of Richard & Sheila Stapley

All Content, Articles, Pictures & Diagrams as Presented are the ©

Copyright of LaymarCrafts & Richard Stapley

Last update 06 January 2009

All Rights Reserved |

|

Web Site Design & Construction by

Richard Stapley. |