| LaymarCrafts Woodturning | Hints & Tips |

| Belt Sander Modifications and Jigs Pt. II |

Since I made my original Tool Grinding Platform for the Belt Sander I have adapted it to enable me to more accurately Grind various other Chisels such as the Skew and many of my Own Design Tools.

For this I attached a Semi-Circular Platform to the Original Angle Platform and added various Guides to enable me to work with not only Simple Angles but also Compound Angles as well as giving a more versatile means of Support and Guidance.

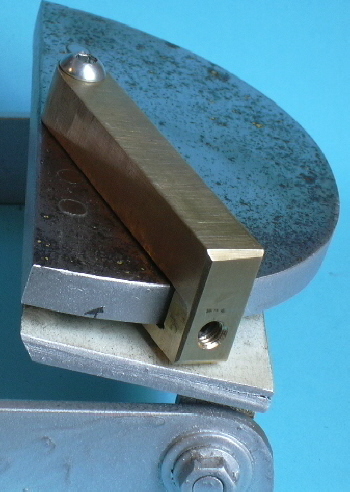

For the Guide I used some 12mm [½"] sq. Brass, the Locking Screw [M6 Grub Screw] part is also cut from the same Brass Bar and Silver Soldered to the main bar as shown, this gives two Clamping Points for a solid and accurate Guide.

|

The other two holes are also drilled and tapped to suit [M6] these are for attaching to the Main Platform and Spacer. When Making the Spacer allow for the free movement of the Guide. In the picture right, you can see the final assembly and if you look carefully you can see the Brazing Line just above the Tapped Hole for the Grub Screw, you can also see the ends of the Screws fixing the Semi-Circular Platform to the Main Platform. Although the intention was to make this a bolt on addition it has become a permanent attachment as it performs all the functions of the original Platform. The piece of Steel I used was a bit "Pitted" but having sanded it back, on the Belt Sander, it is relatively smooth and does not create any problems. You may well have to Chamfer the leading edge, depending on how close you need to have the Platform to the Belt Sander, generally this is only a concern when using the Platform at relatively Steep Angles. |

|

View from above of the Platform and Swivel Arm.

Angle Gauges

To enable the quick and accurate set up of the Platform, Angle and Guide Bar Angle I made a set of Angle Gauges from Aluminum off cuts, these were approximately 100mm x 40mm x 3mm [4" x 1½" x ⅛"] however the actual size and material used is not important, they could just as easily be made from Wood.

By setting the Platform to the required angle you can then sand or grind to your chosen piece of material to the correct angle, a Gauge for any angle can be made to suit the so called Standard Grind Angles or to your own preferred Grind Angle.

| Gauges for the

following Grind Angles:

90° or any Angle to suit your own requirements. |

The same Gauges are used to set the Guide Angle for simple Angle Grinding with the Platform at 90° or Compound Angle Grinding with the Platform set at the desired Angle.

|

|

Vee Guide

A Vee Guide is a useful addition and will help when Sharpening "Round Tools" in particular Tool Bits for Boring Bars and other Hollowing Tools, and Cutting Tips with the Tormek SVD-185 Jig.

Ideally this should be made in such away that it can be clamped in position or be capable of rotation from the central pivot point.

| By

welding a piece of Steel Angle to a length of Steel Bar as shown in the

diagram you have a very versatile little guide.

The Flat Steel Bar was 50mm x 25mm x 6mm [2" x 1" x ¼"] and the piece of Steel Angle was 45mm [1¾"] of 20mm x 20mm [¾" x ¾"] Steel Angle. In one end of the

Bar you will need to drill a 7mm [5/16"] Ø Hole for the

Pivot/Clamping Screw and Radius the end so that the Bar will not foul

the Belt when in use. |

| This

Guide can be Clamped in position or Rotated about the Pivot Point using

the same Pan Head Screw in the central M6 Tapped Hole [¼"

Threaded].

Although the length of the Guide is not important it should be long enough to give adequate support but not so long that it could restrict its use with shorter/smaller tools due to the Tool Handle fouling. The platform is 125mm [5"] across and therefore 62.5mm [2½"] from front to back with the "V" Guide being 45mm [1¾"] long. |

|

|

LaymarCrafts Woodturning is the Web

Site of Richard & Sheila Stapley Last update 06 May 2008

|

|

Web Site Design & Construction by Richard Stapley. |