| LaymarCrafts

Woodturning |

Information |

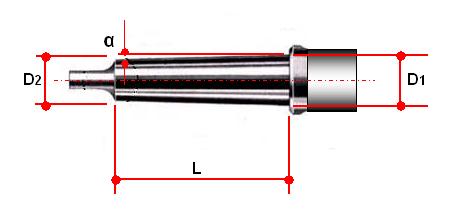

| Dimensions

of the Morse Taper

The most

common Taper in use on the Lathe is the Morse Taper, although there are many

other types of Taper in use, these are generally for use in Mechanical and

Precision Engineering Disciplines, such as Collet Chucks for Milling, and

therefore not often encountered by the Woodturner.

|

|

The Standard

Dimensions for the various Sizes of the Morse Taper Shank are given below.

|

Taper

Size |

Ø

D1 |

Ø

D2 |

Taper/Ft |

Taper/Inch |

Angle

α |

L |

| #1 |

0.4750"

12.065mm |

0.3690"

9.373mm |

0.5986" |

0.0499" |

1.4287° |

2.13"

54.10mm |

| #2 |

0.7000"

17.780mm |

0.5720"

14.529mm |

0.5994" |

0.0500" |

1.4307° |

2.56"

65.02mm |

| #3 |

0.9380"

23.825mm |

0.7780"

19.761mm |

0.6024" |

0.0502" |

1.4377° |

3.19"

81.06mm |

| #4 |

1.2310"

31.267mm |

1.0200"

25.908mm |

0.6233" |

0.0519" |

1.4876° |

4.06"

103.12mm |

| #5 |

1.7480"

44.399mm |

1.4750"

37.465mm |

0.6315" |

0.0526" |

1.5073° |

5.19"

131.83mm |

| #6 |

2.4940"

63.348mm |

2.1160"

53.746mm |

0.6257" |

0.0521" |

1.4933° |

7.25"

184.15 |

All dimensions are in

inches with Metric [mm] equivalents for major dimensions.

D1

= Large End of Taper Diameter.

D2

= Small End of Taper Diameter.

α =

Angle of Taper.

L =

Length of actual Taper Section.

Overall

Length of the Morse Taper will depend on the individual designs from the

Manufacturer and the variance for items attached to the Morse Taper.

|

LaymarCrafts Woodturning is the Web Site

of Richard & Sheila Stapley

All Content, Articles, Pictures & Diagrams as Presented are the ©

Copyright of LaymarCrafts & Richard Stapley

Last update 16 July 2007

All Rights Reserved |

|

Web Site Design & Construction by

Richard Stapley. |